We know we aren’t the only NDT service company in the industry – but we have faith that our particular sets of expertise, personnel, and experience allow us to deliver what others cannot.

Choosing Vertech Group for your NDT services comes with several unique advantages that set us apart from the rest. Our commitment to excellence, comprehensive knowledge of various testing methods, and an unyielding focus on customer satisfaction are among the many reasons why we are a trusted name in nondestructive testing.

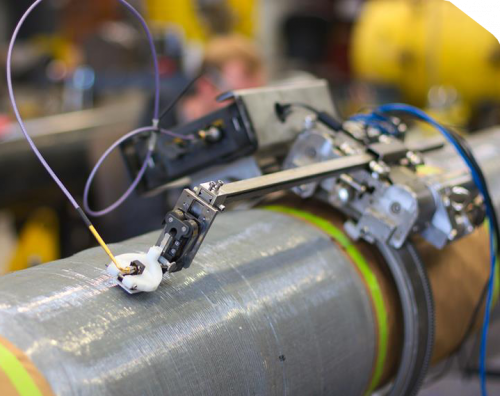

We have invested in state-of-the-art equipment and continual staff training to ensure we deliver reliable and efficient NDT methods.

Our team of certified technicians possesses a deep understanding of various testing methods. Whether it’s liquid penetrant tests, visual inspection, or ultrasonic tests, we ensure each method is tailored to meet the specific requirements of your project. Our broad experience allows us to choose the most effective approach for each situation, guaranteeing optimal results every time.

At Vertech Group, customer satisfaction is at the heart of our service delivery. We aim to provide our clients with the most detailed, accurate, and efficient nondestructive testing services, all while maintaining open lines of communication. We believe that understanding our client’s needs and expectations is key to our success.

We offer an unmatched combination of advanced technology, in-depth expertise, and customer-centric services. With us, you can rest assured that your project’s integrity is in safe and capable hands.