Vertech New Zealand takes immense pride in our extensive experience and proficiency in providing top-notch inspection and testing services to the dairy industry in New Zealand. Our unwavering commitment to excellence and dedication to product quality and safety has made us a trusted partner for numerous dairy-related businesses nationwide.

Dairy Plant Inspection

Vertech New Zealand is committed to the growth and success of the New Zealand dairy sector. We recognise that dairy plays a pivotal role in the country’s economy and are dedicated to ensuring its success. Our commitment to quality, safety, and regulatory compliance is unwavering.

WHY CHOOSE VERTECH NEW ZEALAND FOR DAIRY INDUSTRY INSPECTION?

Whether you are a dairy farmer, processor, or distributor, Vertech New Zealand is your trusted partner for inspection and testing services. We provide the assurance you need to deliver safe, high-quality dairy products to consumers while maintaining the integrity of your brand.

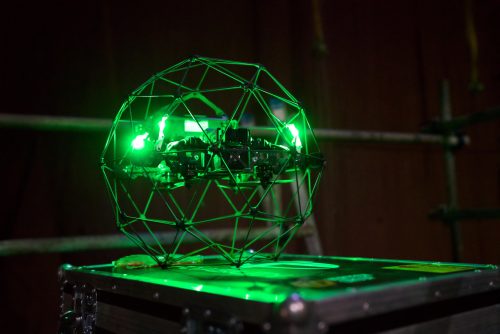

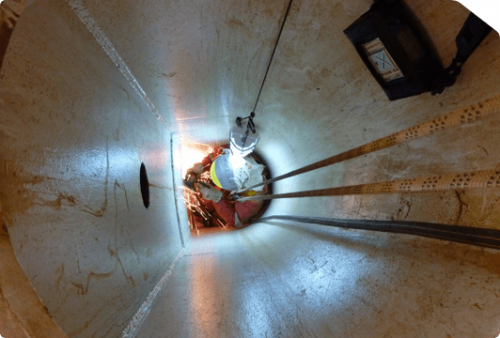

Contact us today to discover how Vertech New Zealand can support your business in the dairy industry through our expertise in visual inspection, NDT, rope access, drone inspection, and RDVI inspection. Our dedicated team is ready to discuss your needs and develop a tailored plan to ensure your success in this essential sector.