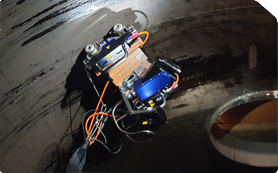

Vertech apply Advanced-RDVI as an integrated solution with a focus on pre-planning and specialist execution packages to deliver high levels of data & results that can not only be used for pressure equipment sign off, but also for post inspection analysis, risk reviews and process operational requirements.

The Vertech Advanced-RDVI team has over 60 years of RDVI experience, gathered from a variety of industries including Oil, Gas, Petrochemical, Pharmaceutical, Dairy and Power Generation from all across the globe.